What is jidoka? Here are the ins and outs of this Lean essential

Georgina Guthrie

September 02, 2020

Lean is all about achieving more with less — something that all businesses want. A big part of achieving this is through creating an efficient workflow. The team is constantly meeting orders, while continually minimizing waste. In Lean management, this process is achieved gradually, through small, incremental steps — something that’s known as continuous improvement. But continuous improvement as a process focuses on waste and production efficiency — not so much on the quality of the product. This is where jidoka comes in.

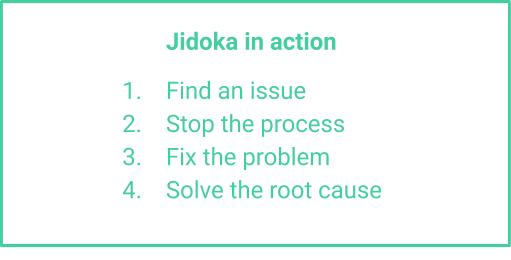

Jidoka is all about sticking to your workflow while making sure your product meets the high expectations of your customers. Or in other words, it’s built-in quality. Using four steps, and it helps you pause production while you identify and work out the cause of the issue.

Next, we’ll go into the full jidoka definition, plus get a closer look at how you can apply this handy technique to your own processes.

What is jidoka?

Jidoka, also known as ‘autonomation,’ is a way of ensuring quality in manufacturing and product development. If an error is detected, it helps you ensure you maintain your takt time. You can automate the first two stages, while the other two usually require manual effort. For this reason, many call it ‘intelligent automation’ or ‘automation with a human touch.’

Jidoka consists of the following four steps:

These four steps can be applied to any industry and are highly useful for addressing quality issues without bringing the whole operation to a standstill—a scenario no business owner wants.

Why is Jidoka important?

Jidoka can help you spot and stop quality issues before they move down the value stream, where they’ll often cost more to fix. Here are the three main issues that jidoka addresses:

- The defective product continues to be made, and additional stages are added that may need to be abandoned, wasting time and resources.

- The issue is spotted, and the product is repaired, which will take additional time and resources. Often at considerable cost, if the product is near the end of production.

- If there’s a long delay before the issue is found, a large number of products will be made and either need to be abandoned, or salvaged.

What’s the difference between Jidoka and Just In Time (JIT)?

Jidoka is one of the pillars of the Toyota Production System. The Just In Time (JIT) method often overshadows it, but the two do have key differences.

JIT focuses on workflow. It’s about optimization by reducing production times. If certain processes don’t add value, we call them a waste and eliminate them. The main goal is to save time.

Jidoka, on the other hand, is more focused on alerting the team that time waste is about to happen through defects. So both are focused on preventing time waste, just in slightly different ways.

How to apply jidoka to your industry

You can even apply Jidoka to knowledge-based industries — and in many instances, the first two steps can be automated.

For example, in software development, continuous delivery involves automatic testing and rejecting of code. If this happens, it goes back to the dev team to work on and fix the problem. In fact, the Toyota folks who invented Lean thought of this too and gave it a name: Poke-Yoke, which is all about catching issues before moving onto the next stage. Implement this, and you’re halfway there.

Once you’ve detected the problem, those responsible for the project can focus on fixing the issue (step three). Once it’s been fixed, the team can delve into the whys using a root cause analysis (or fault tree analysis). After locating the root cause, teams can then decide on whether to move forward with a fast, temporary fix. This would keep production moving, or they can continue putting more resources into a solution.

Jidoka tools

Jidoka is a Lean manufacturing heavyweight and a must for ensuring quality in your production. Of course, you can customize it according to your way of working. For example, there are varying degrees of automation you can apply to steps one and two. Plus, any number of people to work on steps three to four, depending on the severity of the issue.

A great thing about this process is its simplicity. It’s easy to remember, effective, and offers a clear roadmap for what to do in the event of a problem.

To make the process that little bit easier, invest in tools to help you track the process. Backlog, our project management tool, includes automatic tracking features, so progress updates are as simple as logging in and checking your notifications. Teams can also use Kanban boards and progress charts to see both how their colleagues are doing, and where their work fits into the bigger picture—something that’s especially useful when you need to fix issues while keeping things moving.