Forget batch work — continuous flow is your ticket to a more efficient way of working

Georgina Guthrie

September 11, 2020

When car magnate Henry Ford famously said, ‘You can have any color, so long as it’s black,’ he inadvertently highlighted a big issue with batch manufacturing: a lack of flexibility. What if you don’t want a black car? You have to wait until you finish an entire batch before you can move on to another option. Multiply that by several colors, cars, and orders, and you can see how wait times add up.

This is where another car manufacturer stepped up and changed the game: Toyota. Toyota Production Systems, as it’s formally known, invented a process of continuous flow — and it’s been changing manufacturing and just about every other industry since. Here’s everything you need to know about this Lean management essential.

What is continuous flow?

Continuous flow is a not-so-distant cousin of just-in-time and Kanban approaches. All focus on speeding up production flow and reducing waste through ongoing improvements.

With continuous flow, the goal is to create a one-piece flow system whereby one item can move through every step into the entire process, instead of working in batches.

To use a real-life example, imagine a bakery has to create 100 wedding cakes. A batch process would be to focus all your efforts on making the base of a cake, times 100. Then the next tier, until they’re all done. Then the final one, then icing, and so on. The end result is that there’s a large gap where nothing’s produced, and then — BAM! 100 cakes.

With a continuous flow setup, the bakery would start with the base, then, rather than putting it to one side and moving onto the next base, move it through to the next stage of production (tier two), and so on until it’s iced and ready to go.

The end result is that you have one complete wedding cake ready to go, in a much shorter time. Keep this process moving, and you have a continuous stream of wedding cakes flying out your bakery doors. Customers don’t have to hang around until 100 are ready. Plus, your bakery doesn’t have big stretches of time where the counter staff have nothing to do.

This trick applies to bakeries, but it also works for knowledge industry jobs: from software development teams to marketing agencies.

What are the limitations of continuous flow?

Producing one item at a time, or working in small batches improves speed while improving the ratio of value-added to non-value-added work. It also reduces changeover time (something that happens whenever someone needs to move onto a different stage of the process is also considered waste, and limits the resources for value-adding work, while increasing handling time and complexity.

That said, there are some considerations to bear in mind: Your batch size needs to be balanced against the resource capacity at the value-adding processes.

Or, in other words, you can only work with what you have — and if you don’t have enough resources to do each stage by itself, you may need to work with slightly bigger batches. For example, if there are ten steps to creating your wedding cake, but you only have five staff members, you’ll need to batch some stages.

Three Lean tools to help you fine-tune your continuous flow

#1: Takt Time

Takt time is an essential part of continuous improvement. It’s basically the beat of a business that keeps things moving forward. Similar to how a conductor keeps their orchestra in time and works together with a baton.

It’s the speed at which your item must be completed if orders are to meet customer demand. It helps you keep up with a continuous workflow while minimizing waste due to overproduction or overstorage.

We’ve written more about takt time, so read the full post for the ins and outs of this useful continuous flow method.

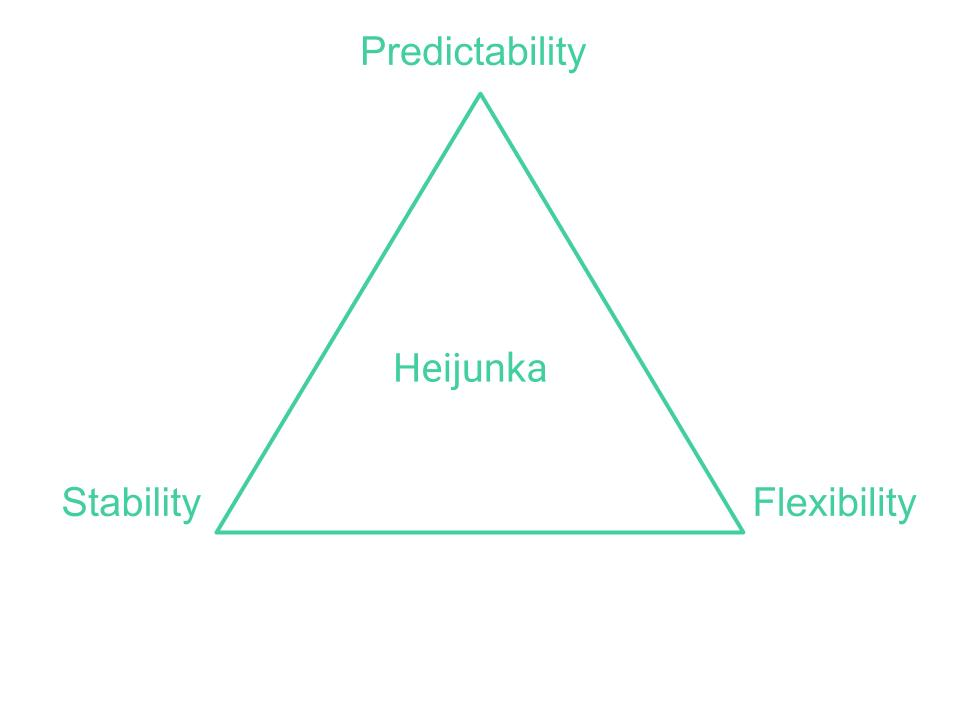

#2: Heijunka, or production leveling

Heijunka (also known as ‘production leveling’ or simply ‘leveling’) is the process of leveling the type and amount of production over a defined period of time. It works in tandem with takt time: The latter helps you define your production pace, and Heijunka helps you stick to it.

Heijunka helps you avoid batch work and produce items according to customer demand. Or in other words, produce as much as is needed, when you need it.

There are two types of Heijunka:

- Leveling by volume averages orders out over a set period of time. The goal is to avoid workflow fluctuations. To go back to our bakery — say it receives 100 orders for wedding cakes throughout the week, which comes in as 60 on Monday, 10 on Wednesday, and 30 on Thursday. The bakery will use heijunka to level that amount by producing an even number throughout the week, rather than tying itself to that exact sequence.

- Leveling by type allows those who produce different types of things to maximize efficiency by minimizing equipment changeovers while making sure there’s buffer stock in place to deal with downtime and demand fluctuations.

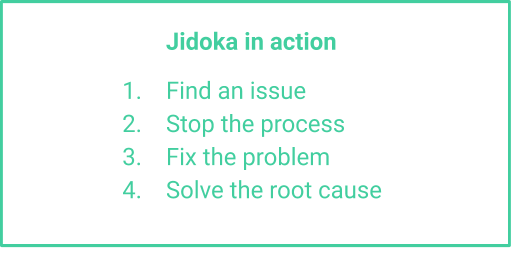

#3: Jidoka

Whereas takt time and heijunka are centered around efficiency and time, Jidoka (aka ‘autonomation’), is a way to ensure quality. But with timesaving as the outcome.

Essentially, it’s a process that helps you detect errors in your product while keeping up with your takt time. It’s often referred to as ‘intelligent automation’ or ‘automation with a human touch’ because the first two stages can be automated, which streamlines the whole problem-spotting process.

Continuous flow tools

Continuous flow is a handy lean tool. It helps you get the most out of your workflow while delivering more value to your customers.

The good thing about this process is that you can flex it around your resources. You can go with the full one-piece flow and produce a single item at a time, continually. Or, you can bundle processes together, or increase or decrease batch size depending on what you have available. It’s a simple principle that you can apply to any workflow. Whether you’re a large, multi-staff factory, or a small software development team.

Using project management software is essential here. It streamlines the whole process with things like automatic notifications and progress reports, meaning team managers don’t need to worry about chasing status updates. Backlog, our project management tool, also features Kanban boards so team members can keep track of jobs and see how their colleagues are getting on in real time. It’s also completely online, which helps managers keep production running smoothly. Whether the teams spread out across different offices, time zones, or even different continents.